why grease trap compliance matters now

Dubai’s foodservice sector operates at high speed and under strict regulatory oversight. As municipalities increase inspections and enforcement for FOG (fats, oils, grease), kitchen managers need smarter ways to avoid fines, downtime, and reputational damage. Smart Sensors for Grease Traps bring real-time visibility to a formerly invisible problem, helping restaurants, hotels, and central kitchens meet Dubai Municipality expectations while improving operations.

What are Smart Sensors for Grease Traps?

At their core, Smart Sensors for Grease Traps are compact IoT devices designed to monitor grease levels, water flow, and trap performance. Installed inside or above the grease trap, these sensors measure:

grease accumulation and layer thickness

water flow rate and sudden backflow

temperature and pH (on advanced models)

Data is transmitted to a cloud platform, where alerts, logs, and reports are generated automatically. This allows facility managers to know the exact moment a trap approaches capacity — without waiting for a scheduled manual inspection.

Smart sensors combine several technologies:

ultrasonic or capacitive sensing to gauge grease layer depth

flow meters to detect slow drainage or reverse flow

wireless connectivity (LTE, NB-IoT, or Wi-Fi) to send data to dashboards

cloud analytics to predict when servicing will be required

By connecting with maintenance software, Smart Sensors for Grease Traps turn reactive cleaning into proactive maintenance. Instead of guesswork, you get data-driven schedules and automatic compliance logs.

How Smart Sensors work — a brief technical view

Benefits for Dubai kitchens and facility teams

Implementing Smart Sensors for Grease Traps offers concrete advantages:

1. Real-time compliance and audit trails

Sensors create timestamped records showing when a trap reached critical levels and when it was serviced. This simplifies Dubai Municipality inspections and reduces the risk of fines.

2. Reduced emergency call-outs

Knowing your drain is trending toward blockage lets you plan service in normal hours, not during a costly emergency.

3. Cost savings through optimized scheduling

Rather than fixed-interval pumping, sensors enable condition-based servicing — saving on unnecessary trips and extending the life of traps and pipes.

4. Environmental and sustainability gains

Fewer unnecessary hauls mean lower fuel use and less waste handling. Advanced programs can integrate with FOG recycling partners for greener disposal.

5. Operational continuity

Avoid sudden overflows and kitchen shutdowns — the single biggest threat to guest experience and revenue during high season.

Dubai Municipality and FOG compliance — why sensors matter

Dubai Municipality requires food establishments to maintain grease traps and keep records of servicing and waste disposal. Manual logs are vulnerable to errors and can be questioned during audits. Smart Sensors for Grease Traps automatically produce the documentation inspectors seek:

date/time stamped service alerts

grease accumulation graphs

disposal receipts and service provider links (when integrated)

This digital evidence strengthens compliance posture and demonstrates proactive FOG control to regulators.

Real-world applications: examples from UAE kitchens

- A downtown Dubai hotel installed Smart Sensors for Grease Traps across three kitchens. The system identified unusual grease loading during a weekend festival and prompted an immediate scheduled service before an overflow occurred — preventing downtime during peak occupancy.

- A cloud-kitchen operator used sensors to optimize pump frequency across five sites, reducing monthly pump visits by 30% and cutting hauling costs.

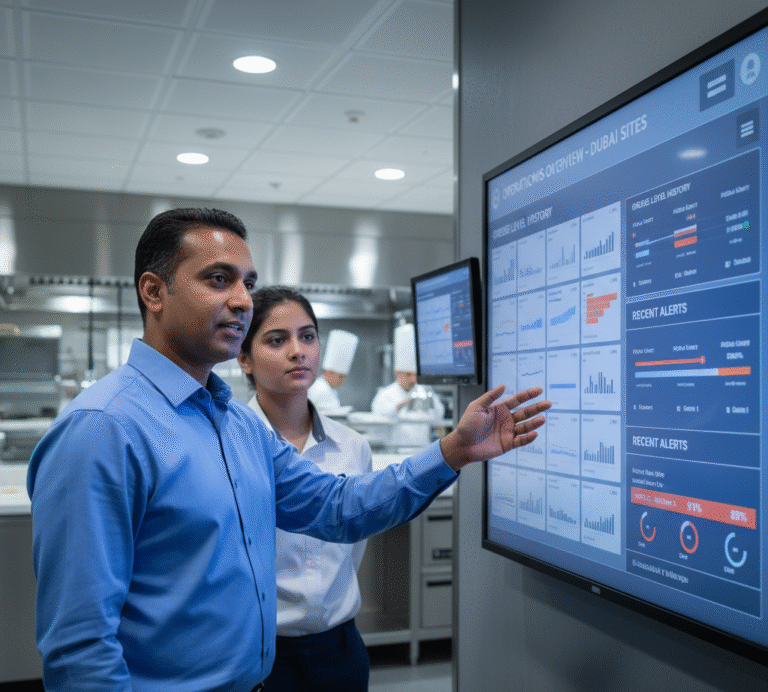

- A hotel group integrated sensor data into its facilities management dashboard to generate municipality-ready reports for multi-site audits.

Implementation considerations for Dubai businesses

When evaluating Smart Sensors for Grease Traps, consider:

Sensor type & accuracy: ultrasonic vs. capacitive — accuracy matters for predictive alerts.

Connectivity: Ensure reliable data transfer (NB-IoT or LTE often better than Wi-Fi in basements).

Integration: Choose sensors that feed into your PMS or CMMS for seamless workflows.

Service partnerships: Work with accredited grease trap service providers who accept sensor alerts and can respond quickly.

Data security: Confirm the vendor follows UAE data protection guidelines and secures telemetry.

Overcoming adoption barriers

Some operators worry about upfront costs or technology complexity. Start small with a pilot in one kitchen or a high-risk site (e.g., busy brunch venue). Use pilot results — reduced emergency calls, lower hauling costs, cleaner inspection records — to build the business case for rollout.

The future: predictive maintenance and AI

The next evolution is using historical sensor data and machine learning to predict grease accumulation based on menu, service volume, and seasonality. Smart Sensors for Grease Traps will not only flag current problems but forecast them days in advance, enabling fully automated maintenance schedules and even automatic service ordering.

a competitive edge in compliance and operations

For Dubai’s F&B decision-makers, Smart Sensors for Grease Traps are no longer a futuristic novelty — they’re a strategic tool. Real-time monitoring protects against fines, reduces downtime, and delivers measurable cost savings. As municipalities tighten enforcement and consumers demand higher hygiene standards, adopting sensor technology positions your operation ahead of the curve.

Ready to modernize your FOG program? Contact our team to schedule a pilot deployment of Smart Sensors for Grease Traps and receive a compliance readiness assessment for your Dubai kitchens.

Most Frequently Asked Question

Smart sensors are IoT devices that monitor grease levels and flow in traps, generating time-stamped logs and alerts that simplify Dubai Municipality compliance and audit readiness.

Yes — by switching from time-based to condition-based servicing, sensors often reduce unnecessary pump visits while preventing emergencies.

Absolutely. Sensors scale from single-site restaurants to multi-site hotel groups and central kitchens, with centralized dashboards for enterprise management.

Depending on configuration, sensors can detect abnormal grease layer growth or flow changes in real time and send alerts within minutes.

Many systems export compliance reports and logs that operators can submit to authorities; API integrations to facility management platforms are also common

ROI varies, but benefits include fewer emergency call-outs, optimized hauling costs, reduced fines, and extended equipment life — pilots in UAE kitchens often show payback within 12–18 months.

Our Services

Our step-by-step guide simplifies the cleaning process, ensuring a hassle-free experience while keeping your traps clean.

Drain Line Jetting

Pest Control Service

Deep Cleaning

business

Our Working Process

Let’s start the journey towards success and enhance revenue for your business. Take your company to the next level.

Book An Appointment Today

Blue Diamond would like to hear from you. if you have business inquiries. Get in touch with us.